By- S. K. Paluskar (Excel Industries Limited)

Detergent formulations are being manufactured by many people all over world for past several years .

Powder, Liquid and bar cake form of detergents are manufactured by most of the detergent manufacturers.

Any Detergent must contain a surfactant system, a builder system, fillers and performance boosters like Optical brighteners, perfumes, colors, bleaching agents etc.

Depending on the expected performance of the detergent, a surfactant system is decided.

Builder system is expected to provide chelation of metallic impurities, suspension of soil ( Anti-Redeposition), enhance detergency ( In Indian context – boost foam too), Provide pH buffering.

As synthetic detergents are largely manufactured using anionic surfactants, a compatible builder systems also are used by manufacturers.

While Soda Ash provides for precipitative type of builder effect and helps maintain pH, STPP has been used by detergent manufacturers as a dispersant builder. STPP has performed all the jobs of a builder faithfully. However, due to environmental concerns governments in many countries have been forcing people to phase out STPP. It is causing problem of eutrophication of water bodies and water bodies are rendered harmful to living organisms.

In order to phase out STPP, alternate builder systems were necessary. Many alternate systems are being used by detergent people today.

Some of them are based on Zeolite. Some are based of chelating agents like EDTA, NTA etc. Many people use Citric Acid ( For liquid formulations ). Each of these products have some advantages and disadvantages.

For example, Zeolite is a water insoluble product itself. It is efficient for controlling Calcium ions only. Zeolite needs activation by a supporting product. Zeolite needs to be supported for Anti redeposition performance.

EDTA and NTA are costly products and environmental concerns are there for both these products too.

Polycarboxylate polymers are commonly being used by many. However the performance of polymers does not match that of STPP.

Phosphonates are a kind of chelating agents available to us since fairly long time. Most of the toilet soaps use “HEDP” in addition to EDTA for controlling Fe ions to prolong shelf life of the toilet soaps. Fe ions catalyse rancidity in soap bar and spoil look, feel, color and perfume of the soap bar.

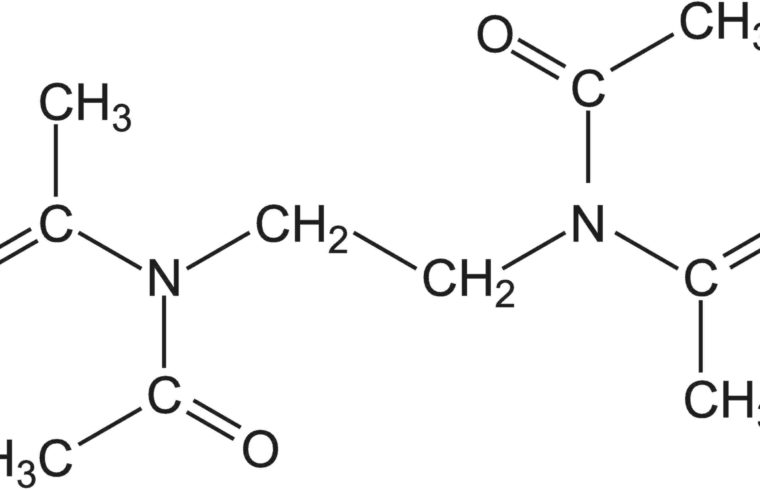

Phosphonates are a family of chemicals and include many members in the family, the typical names are HEDP, ATMP, DTPMP, EDTMP, HMDTMP, PBTC, HPAA, Glyphosate etc.

Phosphonates are also being used in oilfield chemicals for performance in very harsh conditions. Most of the Industrial water treatment processes are based on Phosphonates for controlling scaling and corrosion.

Many textiles processing plants use Phosphonates for controlling influence of Ca , Mg , Fe and other cations in the textiles processes.

Phosphonates are adopted for pharma applications in the name of etidronate, alendronate, zolendronate etc.

Phosphonates are known to show pH stability from 1.5 to 13 pH. They are known to be stable up to 120’C.

Environmentally Phosphonates degrade slowly and pose no risk of eutrophication http://www.phosphonates.org/images/Images/Documents/EPA%20phosphonate%20input%20detergent%20Ecolabel.pdf .

And

http://www.heraproject.com/ExecutiveSummary.cfm?ID=170

Phosphonates exhibit synergistic performance in combinations. They also exhibit synergistic performance with polyelectrolyte polymers.

Many multinationals are known to incorporate Phosphonate products into their detergent formulations to achieve superior performance. This gives them a competitive edge and is a closely guarded recipe.

In the Indian context, STPP is not manufactured in India and therefore cost and availability of this

Excel Industries Ltd. has made this recipe available to detergents manufacturers in India.

Excel Industries Ltd. is manufacturing various chemicals for Industrial application for past 75 years. Chemicals manufactured by Excel Industries Ltd. are used by many sectors like Agrochemicals, Lubricants, Plastic polymers, Pharmaceuticals, Textiles, Soaps and Industrial Water Treatment.

Variety of Phosphonates are being manufactured by Excel Industries Ltd. for last several years and it is now one important producer of Phosphonates in the world.

Excel Industries Ltd. is into business of production of specialty performance phosphonates for special applications. One Important application is Builder for Detergents.

The special phosphonate products developed by Excel Industries Ltd. are called DETCEL.

DETCEL-DS is one leading product for Detergent application. It manages hardness of washing water, improves foam property, enhances detergency and provides for Anti Redeposition property too.

This product can provide effect of STPP in the ration of 1:8. ( i.e. 1 Kg DETCEL-DS can provide effect of 8 Kg of STPP ).

This proportion of performance ensures immense economy on cost of production of detergent.

In order to achieve best Anti-Redeposition performance, a combination with polymer in the ration 1:1 is suggested.

The product can be used as Acidic product along with LABSA slurry with neutralisation with alkali. Alternatively an alkaline derivative; DETCEL-11 is available for convenience of use.

Being liquid in nature, these products can be used in powder / Liquid detergents as well as bar cakes.

DETCEL can be used for dishwash products for anti redeposition performance to get sparkling clean vessels.

Various studies for evaluation of performance of this new product have been done and is found to offer cost saving in detergent formulations along with improved performance, while ensuring removal of STPP from the formulation.

In the detergent manufacturing scenario, these two properties offer competitive edge for every detergent manufacturer.

Very goods👍